DAILY Bites

-

PLINAZOLIN technology is a broad-spectrum insecticide expected to be registered in 2025.

-

The discovery of new active ingredients usually takes over a decade and costs over $300 million.

-

Pest resistance is something that R&D departments pay close attention to.

DAILY Discussion

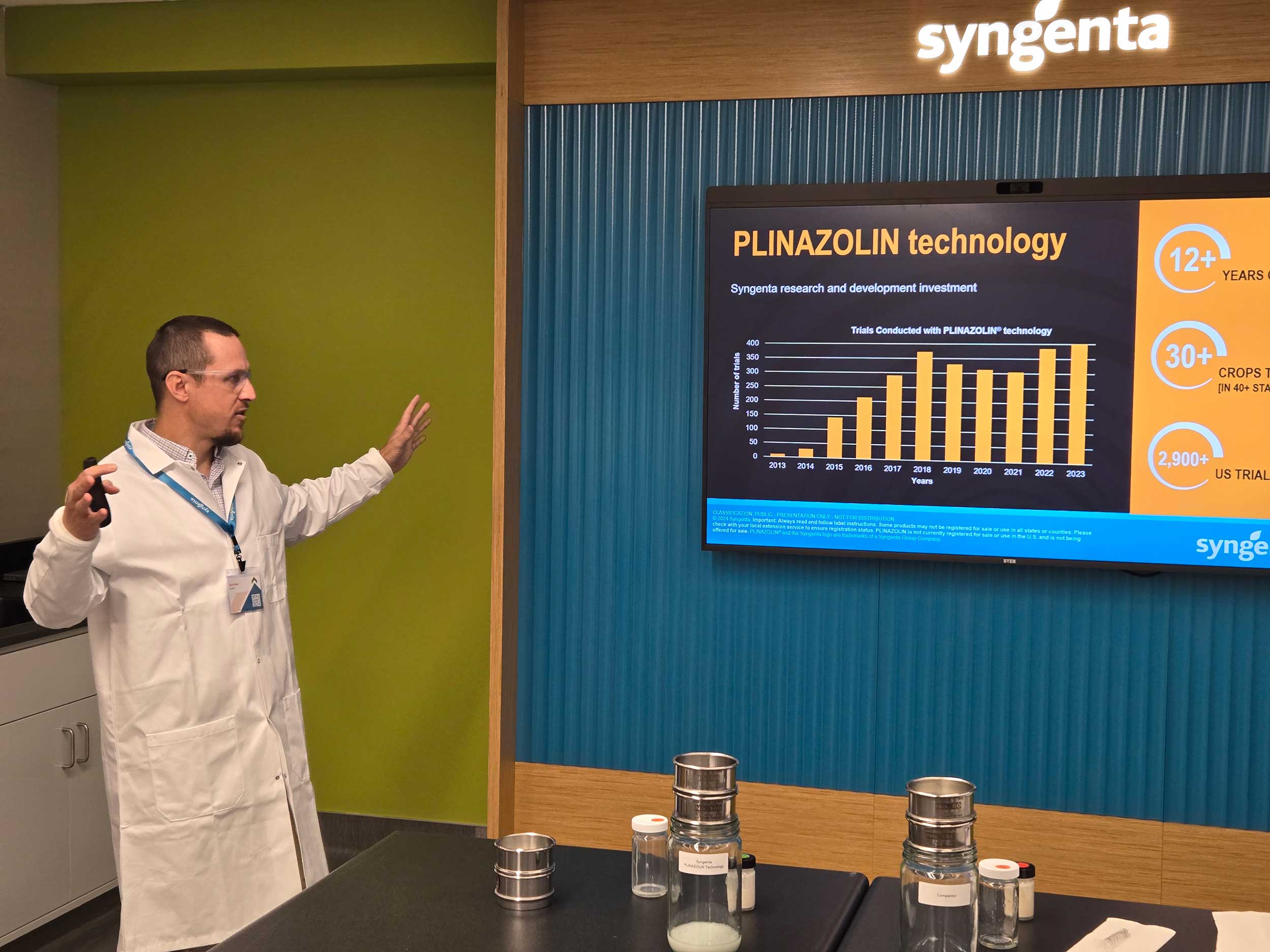

GREENSBORO, North Carolina — With PLINAZOLIN technology anticipated to become registered by the U.S. Environmental Protection Agency in 2025, Syngenta pulled the back the curtain on its R&D process to discuss what went into the development of this new active insecticide ingredient, which is one of its largest regulatory submissions ever.

PLINAZOLIN technology is the trademark name of isocycloseram, an active ingredient that will offer a new mode of action in the IRAC Group 30 foliar space. It will protect against a broad spectrum of agricultural pests, including mites, thrips, beetles, and certain lepidopteran pests.

“We have submitted for registration in numerous crops and crop groups,” said Elijah Meck, Technical Product Lead for Insecticides at Syngenta. Meck and his colleagues discussed the new product at Syngenta’s new North American headquarters facility in Greensboro. “We see a lot of utility with this compound in the crop protection space, as well as seed care and professional solutions.”

Once registered by the EPA, PLINAZOLIN technology will be launched under these brand names in North America:

- Turf: Atexzo insecticide for control of annual bluegrass weevils, mole crickets, bermudagrass mites, billbugs, caterpillars, and European crane flies

- Ornamentals: Vykenda insecticide for control of thrips, mites, leafminers, flea beetles and more

- Professional Pest Management: Vanecto cockroach gel bait for control of all major cockroach species, including German and American cockroaches

Pesticide resistance is a factor for companies like Syngenta in the insecticide space. Over 550 arthropod pests have some kind of documented resistance to pesticides, and more than 60 percent of those are agricultural pests.

That makes new discoveries particularly exciting for those involved.

For example, PLINAZOLIN technology will work against pests such as two-spotted spider mites, which have a documented resistance against 79 different active ingredients.

It’s “just really crazy to think about that pest being able to tolerate or metabolize against 79 different products,” said Kevin Langdon, another Technical Product Lead for Insecticides. “And PLINAZOLIN technology is going to be a really good solution for three of these pests: two-spotted spider mites, diamondback moth, and Colorado potato beetles. …

“We’ve seen really good efficacy against these pests and are really excited to be able to introduce a new tool to growers who experience these pest pressures,” he added.

In today’s marketplace, discovering a new active ingredient — at least one that can be registerable by the EPA — is incredibly difficult and time-consuming. What may start as 100,000 compounds is whittled to 5,000 that may actually get profiled, and then just 30 are evaluated before the single compound is launched.

Trends show that these kinds of discoveries peaked in the late 1980s and into the ‘90s, but since the year 2000, there has been a steady decline in the number of new active ingredients that have been registered.

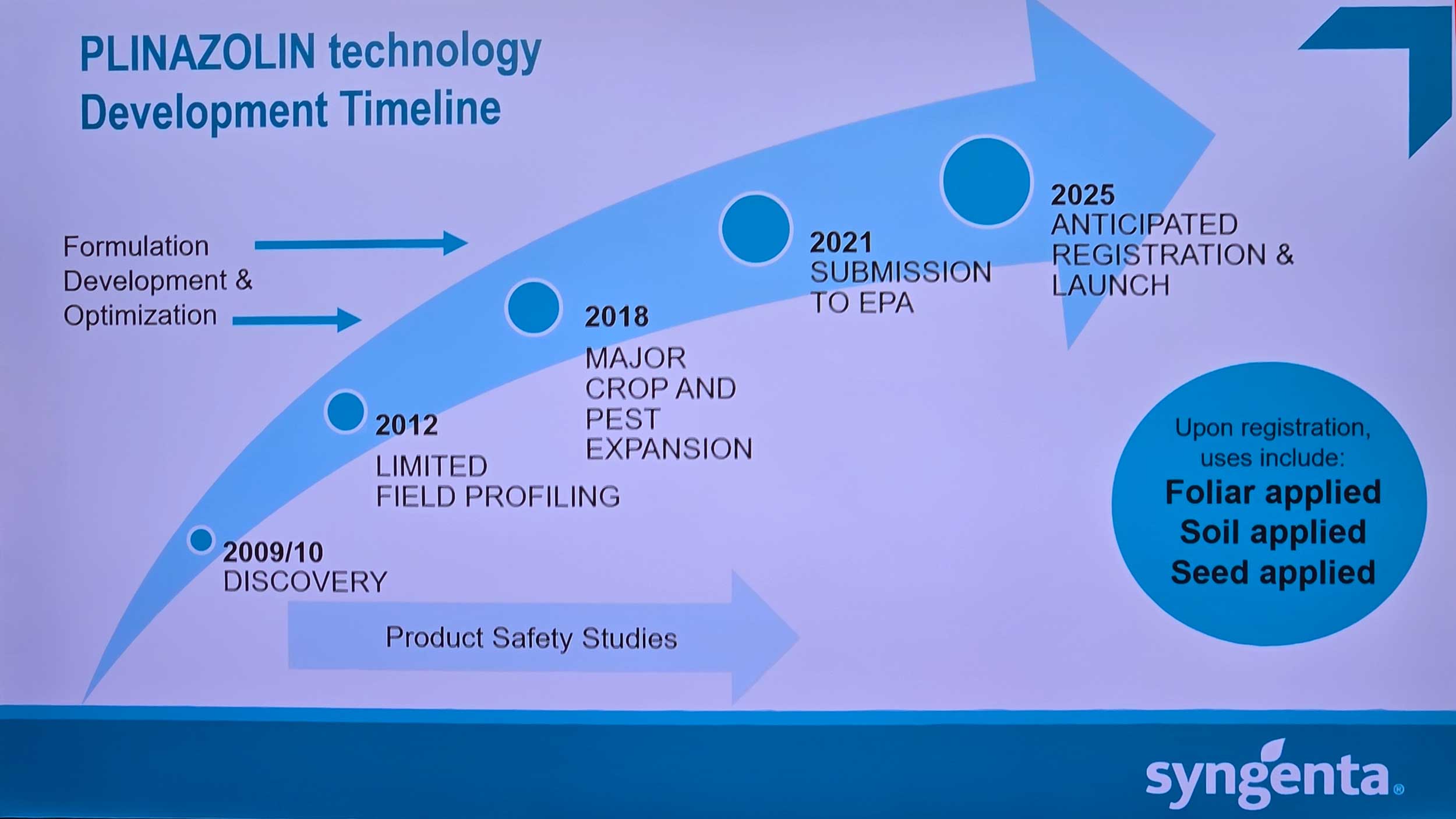

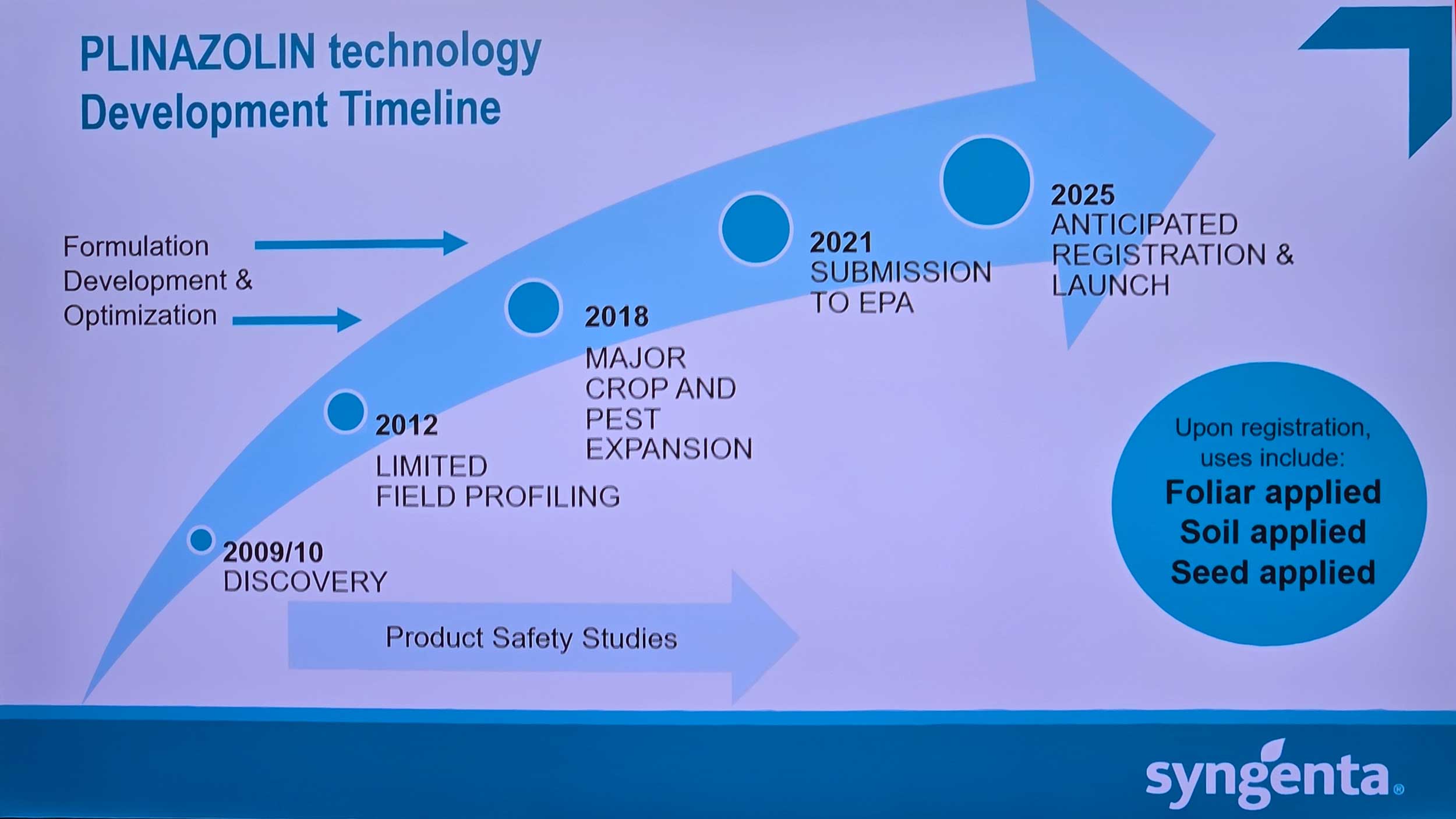

PLINAZOLIN technology itself arose out of a project from the mid-2000s that had to be terminated because of registrability challenges. Around 2010, it was being observed in a greenhouse setting before Syngenta kicked off product safety studies around 2012, which lasted several years to when the company expanded its research into crops and pests.

“We really wanted to focus on what does it mean for the U.S. grower? What does it mean for U.S. crops and pests and so on?,” Meck explained. “So the the focus really came in 2018 — and then in 2021, we submitted to the EPA.”

For these kinds of products, that 10- to 12-year process can be expected to cost north of $300 million, he said.

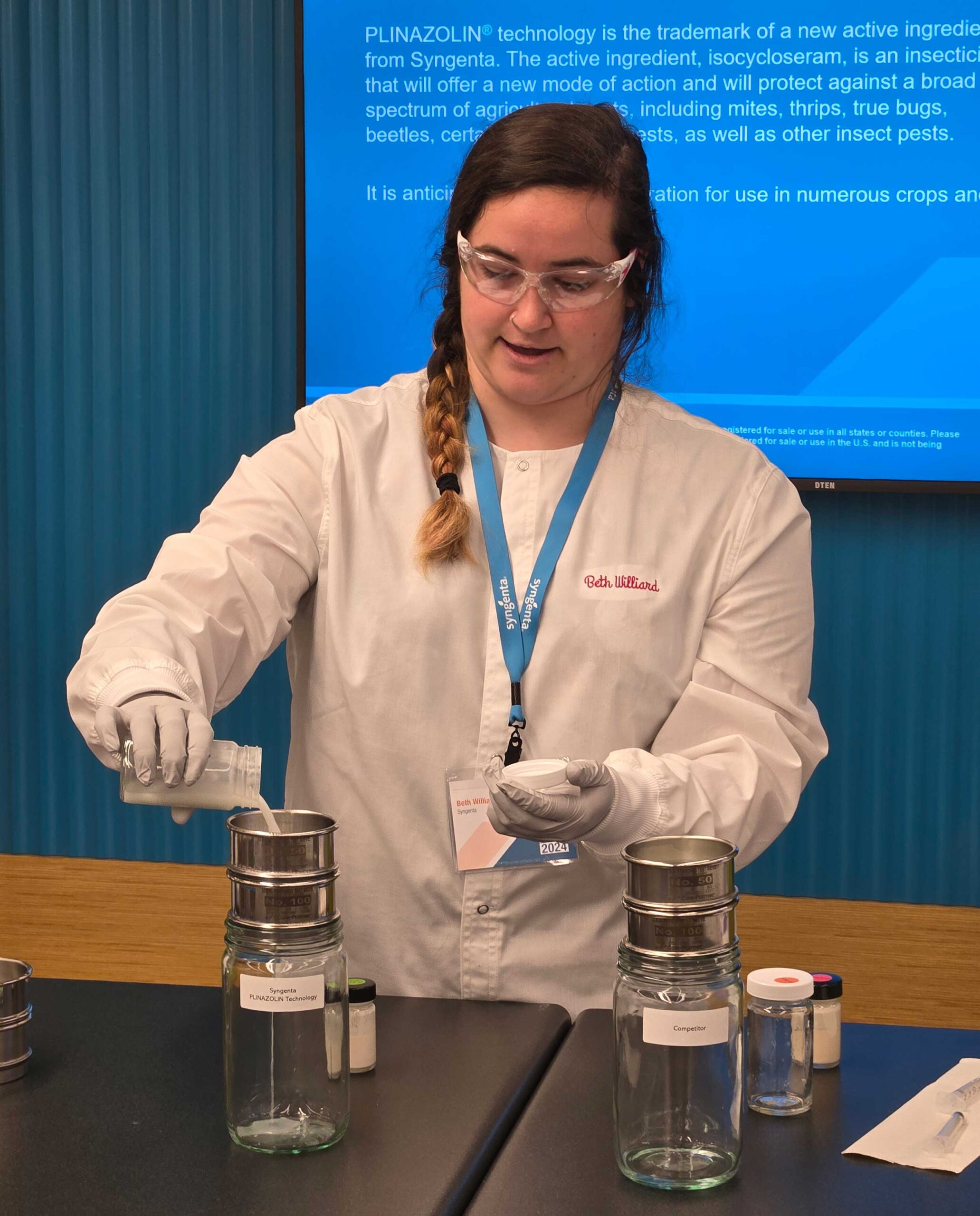

One of the most explored aspects of PLINAZOLIN technology is its formulation. And characteristics like the fact that it is a lipophilic (essentially meaning that it binds tightly to organic matter and soil particles) can be used to help drive the formulation decisions.

Beth Willard, Senior Formulation Scientist at Syngenta, explained that because growers will make a PLINAZOLIN technology application into the furrow at the time of planting, she looked to create a formulation that’s going to be suitable for soil application.

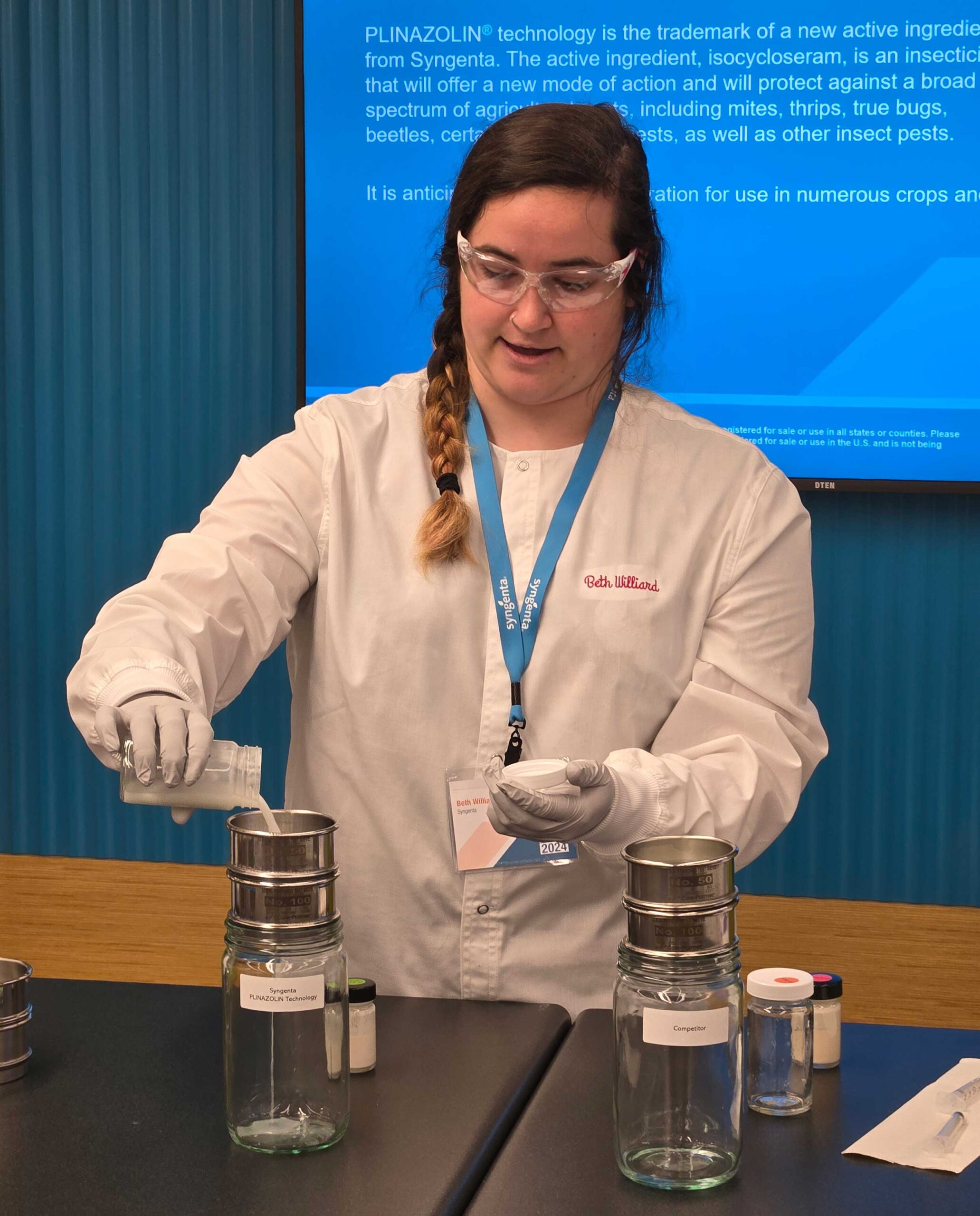

She gave a demonstration in which a product with PLINAZOLIN technology and a competitor’s product were each added to a different jar with meth sieves. It was clear that the Syngenta product was straining through the sieves while the competitor’s didn’t, showcasing how even if an active ingredient is in the tank, it needs to make it through the hose and nozzle and actually be applied to the ground.

Clogging is not a viable option for any grower.

“The first time this happens on our farm, we’re done with the product,” said Indiana farmer Lance Sommer said about crop protection products clogging a machine. “It doesn’t matter how well the product works or can work, if it plugs and we’re busy and we can’t be doing what we want to be doing in the field — planting, spraying — we’re done with the product for good.”

Syngenta tested the PLINAZOLIN technology products in more than 50 different starter fertilizers, aiming to make sure that it plays well in the tank with whatever fertilizer a grower might choose to use on their farm. This comes on top of real-world testing.

“When you have rapid feeding cessation — strong binding to soil particles based on some of those physical-chemical properties, low volatility, low water solubility so it’s not going to leach out of the zone of protection — these are some of the properties that we can take and build that formulation to exploit that particular segment,” Willard said. “Ultimately, we build out a large spectrum of activity, figure out what insects it controls, what it does not, and then from that, what are those insect pests of? And essentially, we take the list of insect pests that it’s active against, we build that into the various crops, and we test in those crops.”

This is an ever-evolving space for growers and the companies creating crop protection products. New active ingredients such as PLINAZOLIN technology are vital to overcoming the resistance that many pest populations can gain with current-market ingredients.

Ryan Tipps is the founder and managing editor of AGDAILY. He has covered farming since 2011, and his writing has been honored by state- and national-level agricultural organizations.

:max_bytes(150000):strip_icc()/BrentHeadshot-3cbbee324858487184bcb64e0c7c3e33.jpg)

:max_bytes(150000):strip_icc()/sioux-falls-river-830fd859abb84cbfb67433d13d5a40f4.jpg)

:max_bytes(150000):strip_icc()/iStock-601942830-2000-eb18c8a4364644918d9f14375bd9b463.jpg)

:max_bytes(150000):strip_icc()/DJI_0580-0780f75a2c2e49e1870e8c0a0f0f2248.jpeg)

:max_bytes(150000):strip_icc()/PhotobyMichaelM.SantiagoGettyImagesGettyImages-1327492732-e774036ebe2c413d827295d94091e084.jpg)

:max_bytes(150000):strip_icc()/Congress-WideShot-2000-5a91ee8f6de542dfa39fc245aef88653.jpg)